Best Practice Cleanroom Design Approaches based on Emission Rates and Contamination Removal Effectiveness

Cleanrooms are among the greatest contributors to energy consumption in today’s rapidly changing world in an energy crisis and climate challenge. We are living on a fragile planet on the edge of dramatic change. We are consumers of our natural resources when we should be custodians. We must move to a circular economy and rebalance our climate before it is too late. What is ironic is that while Cleanrooms contribute significantly to energy consumption Cleanrooms are also part of the solution, interns of clean energy.

The latest ISO 14644-4 Cleanrooms and associated controlled environments, Part 4 "Design, construction and start-up" was published end of 2022. The new ISO 14644-16 from 2019 deals with energy management. Both offer a best practice approach to effective design and operation of Cleanrooms and associated controlled environments.

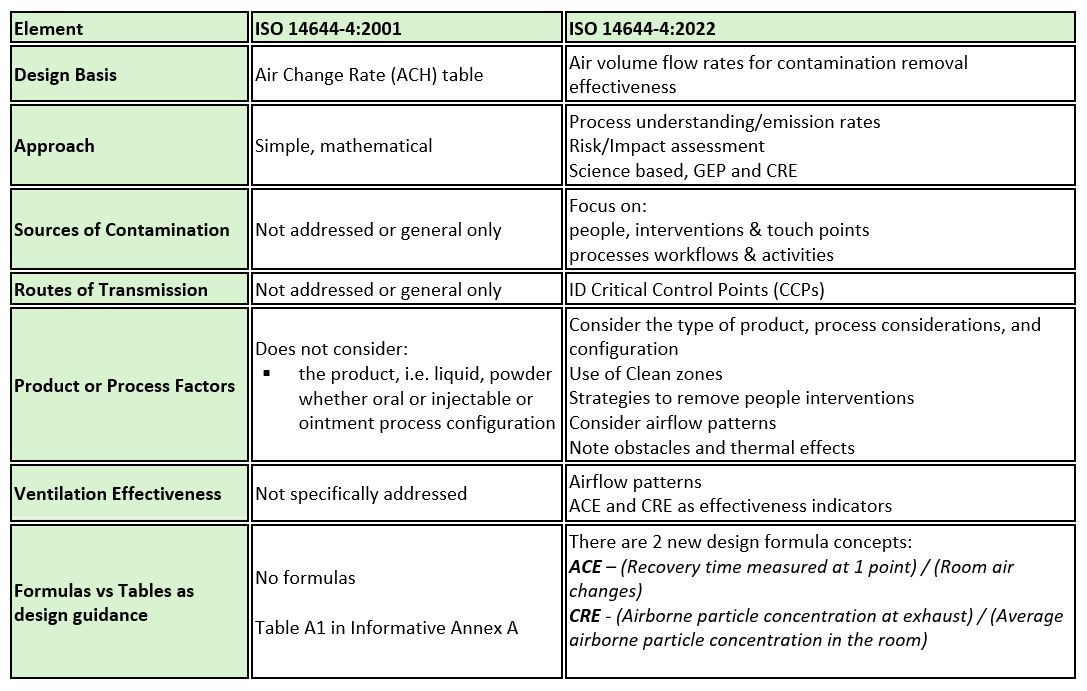

In this our latest blog let’s compare the original 2001 versus the current ISO 14644-4:2020 as it applies to Cleanroom design:

Original ISO 14644-4:2001

1. Focus on Air Changes (ACH):

The old standard used an air change rate (ACH) table as the basis for cleanroom design.

This approach relied on simple numbers provided in Table A1, Informative Annex A, which often led to over-designed or inadequately designed rooms.

2. Simplistic Approach:

Designers used simple mathematical calculations, dividing the total supplied air volume by the room volume.

This method was overly simplistic and did not consider dynamic and static sources of contamination.

3. Lack of Flexibility:

This approach acted as a "crutch" and allowed for a "safe" design that did not always provide the optimal solution for contamination control.

4. Less Emphasis on Scientific Approach:

The design was based on simple numbers without a thorough understanding of particle emissions arising from the dynamic nature of operations in terms of process and people interactions and interventions in the Cleanroom.

Current ISO 14644-4:2022

1. Focus on Particle Emissions and CRE:

The new standard emphasizes particle emissions from people, processes, and activities, including interventions and touch points where contamination transmission can occur.

A scientific data-based approach is introduced, focusing on Good Engineering Practice (GEP) and Contamination Removal Effectiveness (CRE).

2. Flexible and Dynamic Approach:

Design is based on understanding processes, sources of and transfer mechanisms of contamination, and ventilation effectiveness.

Consideration is given to particle generation from various sources and creating optimum airflow patterns for effective contamination removal.

3. Ventilation Effectiveness

Ventilation effectiveness deals with how well the filtered air is mixed with the cleanroom air, i.e. the effectiveness of the airflow patterns.

Understand local airflow patterns, including thermal effects and particular process configurations that can have an impact on product quality, yield, and reliability.

For an existing cleanroom, ventilation effectiveness can be obtained as air change effectiveness (ACE) or contaminant removal effectiveness (CRE).

The selection of the index depends on the application and the data that can be measured or acquired

4. How to Calculate Emission rates using ISO 14644-4:

The formula for calculating emission rates is: S=Q⋅C⋅ε,

where 𝑄 represents the supply air volume (m3/sec),

𝑆 the particle emission rate (numbers/sec),

𝐶 the particle concentration limit from the ISO Class required,

ε is ventilation effectiveness (no dimensions).

There are other formulas and guidance given in ISO 14644-4 (Design) and -16 (Energy Management) but the above gives a simple illustration.

5. Link to the latest Annex 1:

The joint EMA and PIC/s updated Annex 1 asks for a contamination control strategy, CCS based on QRM and an understanding of the risks and impact on product quality and patient safety.

The latest Annex 1 is a “Call to Action” and adopt a holistic approach to contamination control, embracing new technologies and ARMM, including referencing the ISO 14644 family of Cleanroom standards.

Summary of Changes and Key Differences

Key Differences Between ISO 14644-4:2001 and ISO 14644-4:2022 in Cleanroom Design and Contamination Control

Impact of People and Gowning

“It’s all about Airflow Patterns and Contamination Removal Effectiveness”

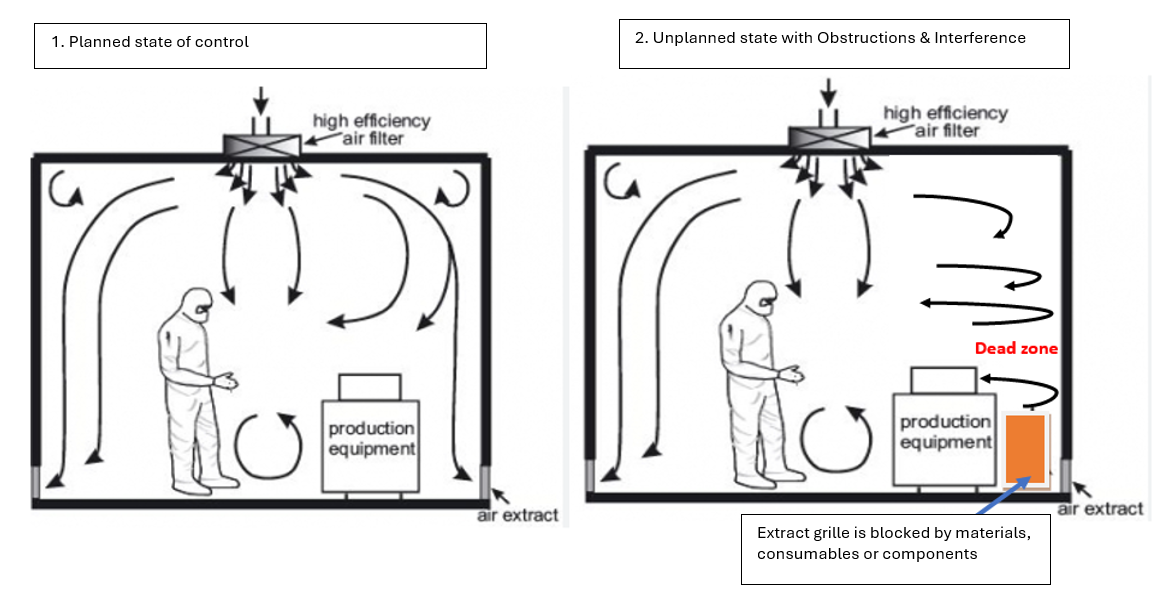

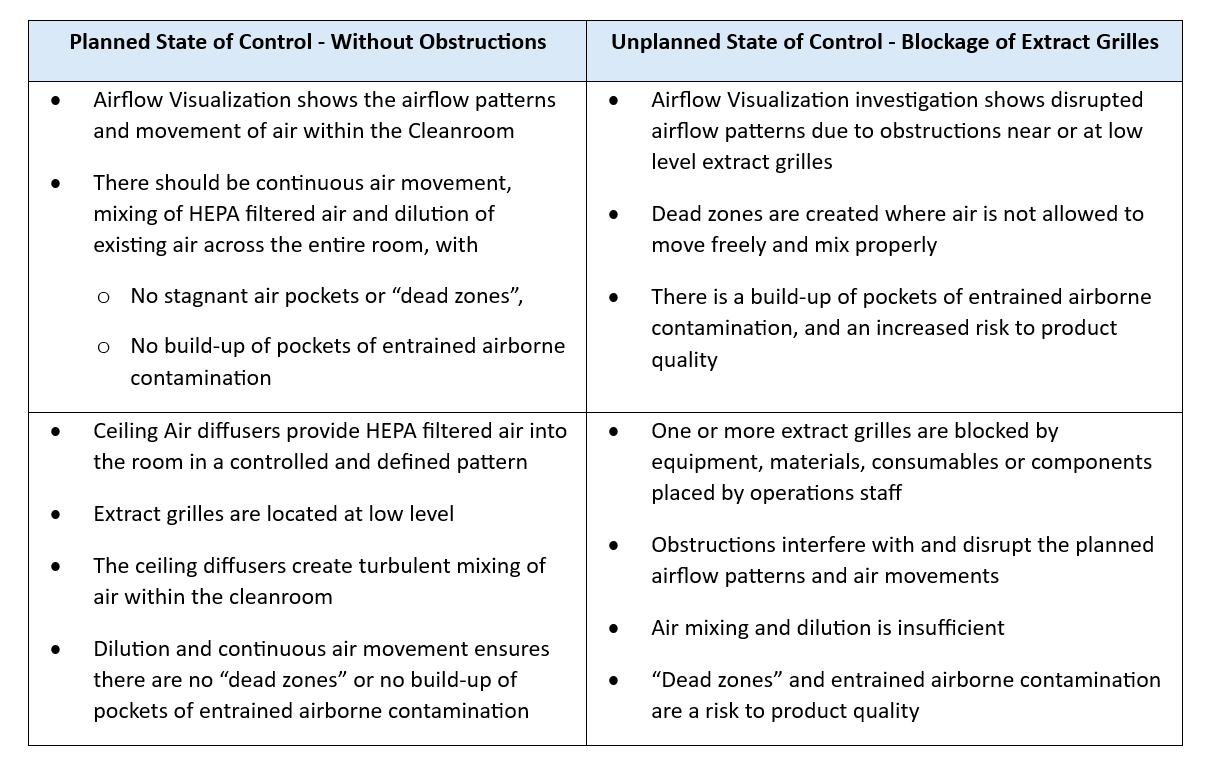

One of the critical metrics in the engineering controls of your CCS (contamination control strategy) is contamination removal effectiveness (CRE); this is achieved through good airflow patterns. Changes in process workflows and operations will change these airflow patterns. Particular attention needs to be paid to ensuring there are no obstructions near or at extract grilles. As most GMP Cleanroom extract grilles are located at low level it is easy to reposition equipment and/or leave containers, trolleys, racking in places that can block airflow movements. These interfere with and create a disruption in the airflow, leading to slow moving, stagnant air or “dead” zones, where air is not adequately mixed and insufficient dilution. These air pockets can contain entrained airborne contamination. This is an operations challenge and ongoing training is essential to ensure awareness of these contamination transfer risks.

Schematic Representation of the Impact of Obstructions in a Non-Unidirectional Airflow Room

So What?

The transition from the former ISO 14644-4:2001 to the current ISO 14644-4:2022 brings a more scientific and flexible approach to cleanroom design. Instead of relying on simple air change rate tables, the new standard considers particle emissions, the impact of various contamination sources, and ventilation effectiveness, leading to more efficient and sustainable cleanroom design.

“Take Home” message:

1. Contamination Sources, transmission routes & Emission Rates are the starting point!

2. Effective Cleanroom design is all about the process, airflow patterns & CRE

3. Air Change Rate is a consequence of best practice Cleanroom design!

There is no “one size fits all” anymore, ergo the importance of good science and GEP, Good Engineering Practice. It comes down to creating the right airflow patterns around the critical control points in the process and contamination removal effectiveness.

Emissions rates from different contamination sources vary considerably and for many different factors. So, we are back to an understanding of the process and activities, using QRM followed by GEP to design an effective CCS (contamination control strategy) based on ISO 14644-4 (Design) and ISO 14644-16 (Energy Management).

At the same time we can optimise our Whole Life Carbon impact on our fragile planet, as part of Climate Rebalancing and moving to a circular economy.

The air change rate is simple mathematical calculation of total supplied air volume divided by the room volume. The underlying assumption is that this is the time taken for the air within the cleanroom to be replaced with newly HEPA filtered air. However this is way too simplistic as they are several contributory factors and from many different contamination sources and emission rates, both static and dynamic.

The reality is that it is the local airflow patterns that produce CRE and an effective contamination control for product quality, yield and reliability. This means we need to carefully consider the room configuration and process layouts, allowing for people activities, movements and interventions. We need to include other effects such as obstructions and thermal effects as these create disturbances in the airflow patterns.

The use of Air Change rate tables as the starting point in cleanroom design is now deemed poor practice and we need to adopt a more scientific approach. ISO 14644 -4 (Design) and ISO 14644-16 (Energy Management), deal with best practice Cleanroom design and optimised operations, in detail, along with formulas for design calculations.

So, “It’s all about Airflow Patterns and Contamination Removal Effectiveness”